Chip manufacturing in Arizona is seeing significant developments, particularly with the investments by Taiwan Semiconductor Manufacturing Company (TSMC). TSMC is making a substantial impact in the Phoenix area with plans to build three leading-edge semiconductor fabs. The investment, totaling over $65 billion, is supported by the CHIPS and Science Act, which is expected to provide up to $6.6 billion in direct funding. This initiative aims to strengthen the U.S. semiconductor supply chain, enhance national security, and create thousands of jobs in Arizona (TSMC) (U.S. Department of Commerce).

Chip manufacturing in Arizona is seeing significant developments, particularly with the investments by Taiwan Semiconductor Manufacturing Company (TSMC). TSMC is making a substantial impact in the Phoenix area with plans to build three leading-edge semiconductor fabs. The investment, totaling over $65 billion, is supported by the CHIPS and Science Act, which is expected to provide up to $6.6 billion in direct funding. This initiative aims to strengthen the U.S. semiconductor supply chain, enhance national security, and create thousands of jobs in Arizona (TSMC) (U.S. Department of Commerce).

TSMC's first factory in Arizona is on track to begin operations by mid-2025, producing 4-nanometer FinFET process technologies. The company also plans to build additional fabs that will focus on advanced 2-nanometer technology, catering to the growing demand for chips in sectors like AI, high-performance computing, and communications (TSMC)(KTAR.com).

These developments are part of a broader strategy to create a semiconductor supply chain cluster in the region, which is expected to drive innovation and long-term growth by bringing together manufacturers, suppliers, research institutions, and other stakeholders (TSMC).

These developments are part of a broader strategy to create a semiconductor supply chain cluster in the region, which is expected to drive innovation and long-term growth by bringing together manufacturers, suppliers, research institutions, and other stakeholders (TSMC).

For more detailed information, you can visit the official announcements from TSMC and the U.S. Department of Commerce, as well as local news coverage from sources like KTAR and the Phoenix Business Journal (TSMC) (TSMC)(U.S. Department of Commerce).

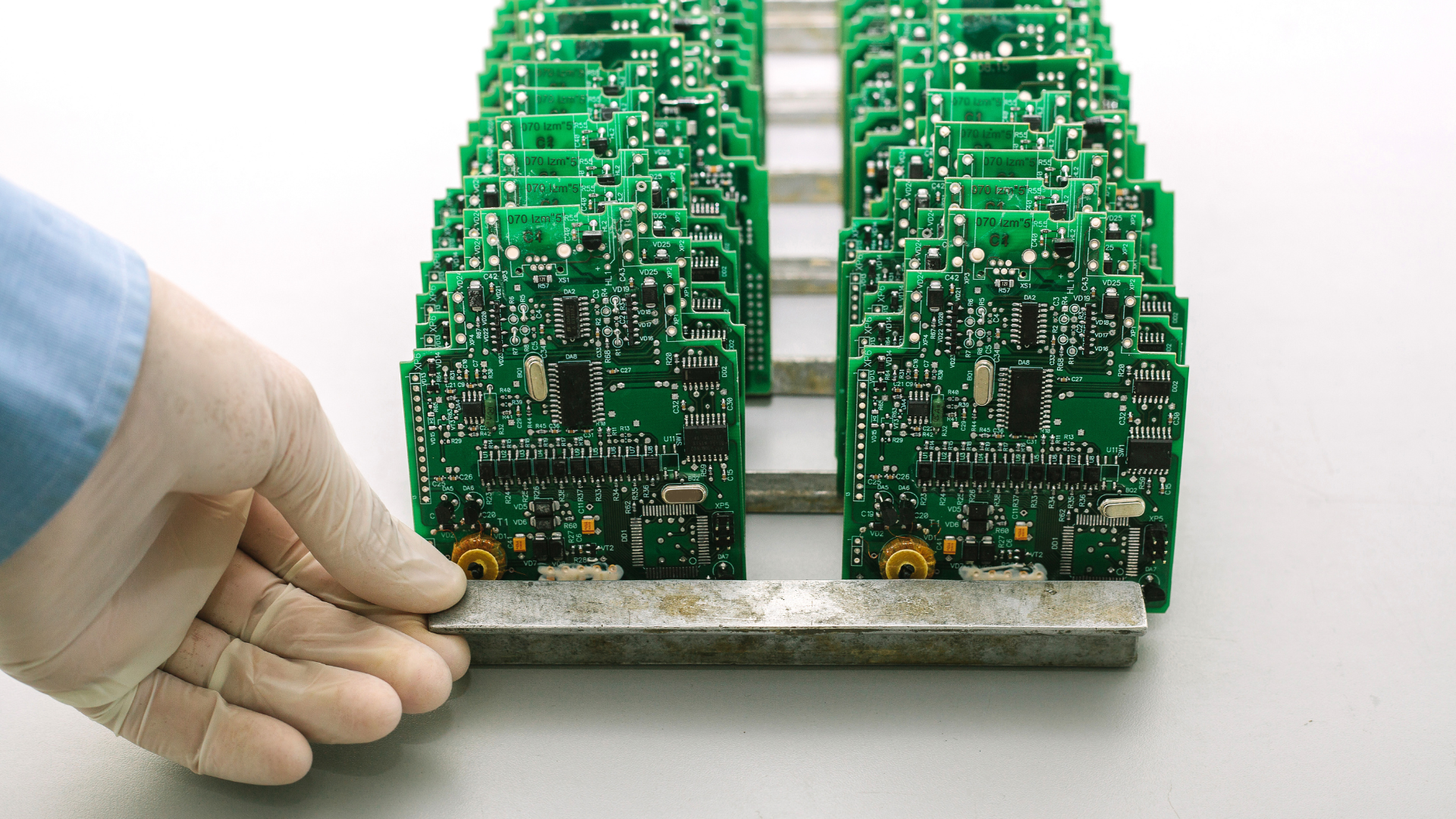

Chip manufacturing is known to use a significant amount of water, which has been a source of concern for some in Arizona. The process of producing semiconductors, particularly the wafer fabrication stage, involves several steps that require ultrapure water (UPW) to clean and rinse the silicon wafers. Here are some key points and resources on the water usage in chip manufacturing:

Water Usage in Chip Manufacturing

Ultrapure Water (UPW) Requirements:

UPW is critical in the semiconductor manufacturing process for rinsing wafers between various processing steps to remove contaminants. The production of UPW itself is a water-intensive process, requiring extensive filtration and purification systems.

Resource: Semi Engineering

Water Consumption Volume:

It is estimated that semiconductor manufacturing facilities, or fabs, can consume millions of gallons of water per day. For instance, Intel’s fabs in Arizona are reported to use about 5-7 million gallons of water per day.

Resource: Reuters

Environmental Impact and Conservation Efforts:

Given the significant water usage, chip manufacturers are increasingly focusing on water conservation and recycling. Many companies are implementing strategies to reduce water consumption and improve water recycling processes to mitigate environmental impact.

Resource: Bloomberg

Case Studies and Industry Practices:

Companies like Intel and TSMC have been investing in water conservation technologies. Intel aims to achieve net positive water use by 2030, meaning they will return and restore more water than they consume.

Resource: Intel

Detailed Examples

TSMC: TSMC's facilities in Taiwan and Arizona use large quantities of water, prompting the company to implement water recycling programs. In Taiwan, TSMC has set up water reclamation plants to recycle wastewater, which is essential given the region's frequent droughts.

Resource: TSMC Corporate Social Responsibility Report

Samsung: Samsung's semiconductor manufacturing in South Korea also consumes large amounts of water. The company has established several water recycling systems to reduce its water footprint.

Resource: Samsung Sustainability Report

Conclusion

Chip manufacturing does use a substantial amount of water, primarily due to the need for ultrapure water in the cleaning processes during wafer fabrication. However, the industry is making significant efforts to reduce water consumption and improve sustainability through advanced recycling and conservation initiatives. For further details, you can explore the provided resources which discuss various aspects of water usage and conservation in the semiconductor industry.

Chip manufacturing does use a substantial amount of water, primarily due to the need for ultrapure water in the cleaning processes during wafer fabrication. However, the industry is making significant efforts to reduce water consumption and improve sustainability through advanced recycling and conservation initiatives. For further details, you can explore the provided resources which discuss various aspects of water usage and conservation in the semiconductor industry.

#ChipManufacturing #ArizonaTech #SemiconductorIndustry #Innovation #EconomicGrowth #TechHub #Semiconductors #ArizonaBusiness #TechIndustry #AdvancedManufacturing